The widest range of solutions on the market

From transport packaging, to unit product packaging, to point-of-sale and point-of-purchase displays and packaging for fresh food and foodservice.

We work with all printing techniques and materials (corrugated, solid board, paperboard and laminations).

How do we achieve this?

Our experience and knowledge of all the sectors we work with allows us to offer a wide range of products.

To ensure that the products of the brands that put their trust in Hinojosa stand out in the market, we have a extensive portfolio of sustainable, innovative solutions adapted to every need.

What do you need and how can we help you?

We are experts in the food sector and develop sustainable solutions focused on fresh produce. Our solutions maximise product visibility, reduce plastic usage and improve recycling rates.

We also have the largest variety of packaging solutions for the agricultural sector: our trays and punnets help producers adapt to new environmental requirements, extend the shelf life of the product and optimise logistics.

We know that the e-commerce sector doesn’t stop growing

The online channel is vital to the growth of many businesses. We help them understand that packaging must create a WOW experience for the shopper. At Hinojosa we are certified in Frustration-Free Packaging, a methodology that uses Big Data to optimise packaging and make it more sustainable without compromising the shopping experience.

We cover the needs of the luxury packaging sector that is in continuous growth. Perfumery, cosmetics, gourmet food or wines and spirits must have customised packaging tailored to the expectations of their market.

POP, promotions and batches: We focus on design and practicality, providing enhanced brand visibility to make your product stand out at the points of purchase and sale. Packaging on wheels serves as an advertising medium and makes transport easier for the end user.

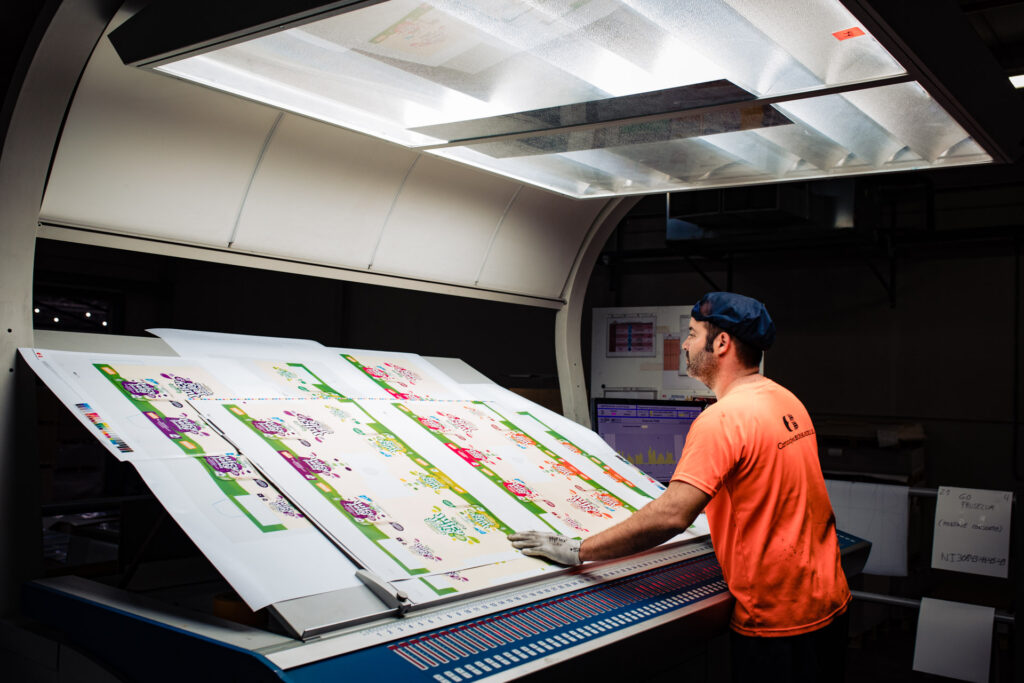

Our printing techniques

High-level Flexo pre-printing and post-printing

Thanks to high-level flexographic post-printing, at Hinojosa we achieve excellent and accurate colour register accuracy for impeccable results. The inks are water-based with a very short drying time, which allows for a very fast printing speed. This technique is especially recommended for large batches where we are looking for the best value for money

In contrast, high-level flexographic pre-printing prints directly onto the paper roll. By using this technique, we achieve high printing quality as it is a smooth surface.

Offset printing

Offset printing technology is perfect for a product that makes an impact. The use of conventional and UVI inks on all types of board results in a clearer and sharper image. Ideal if you want to print a photograph.

Digital printing

Did you know that the first Single Pass printer in Europe was installed in one of Hinojosa’s plants? We are pioneers and specialists in digital printing, an ideal technique for small batches and customers who require the utmost customisation. It allows us to print small batches without printing plate costs.

Why go digital?

- It requires only a single printing step, without lamination

- The maximum plate size is 1,260 mm x 3,600 mm

- We obtain a photographic print quality at 360 dpi.

- We use instant-drying UVI inkjet inks

- It achieves a high printing speed: 50 linear metres/minute

Main advantages of digital printing

No printing plate costs. This makes us more competitive by reducing costs and changing the print as often as necessary.

Shorter lead times and high responsiveness: the process is fully integrated from design to die-cutting. No lamination.

Versatility: we can combine several models within the same order.

Inkjet technology: no physical contact with the plate, in order to keep its physical and mechanical properties intact.

Smaller minimum batches: both due to the combination of models and the use of prefabricated printing plates.

Real colour proofs: these are produced by the machine itself to guarantee 100% accuracy of the final result.